Experience

Over 7 years of expertise in cooling computing equipment.

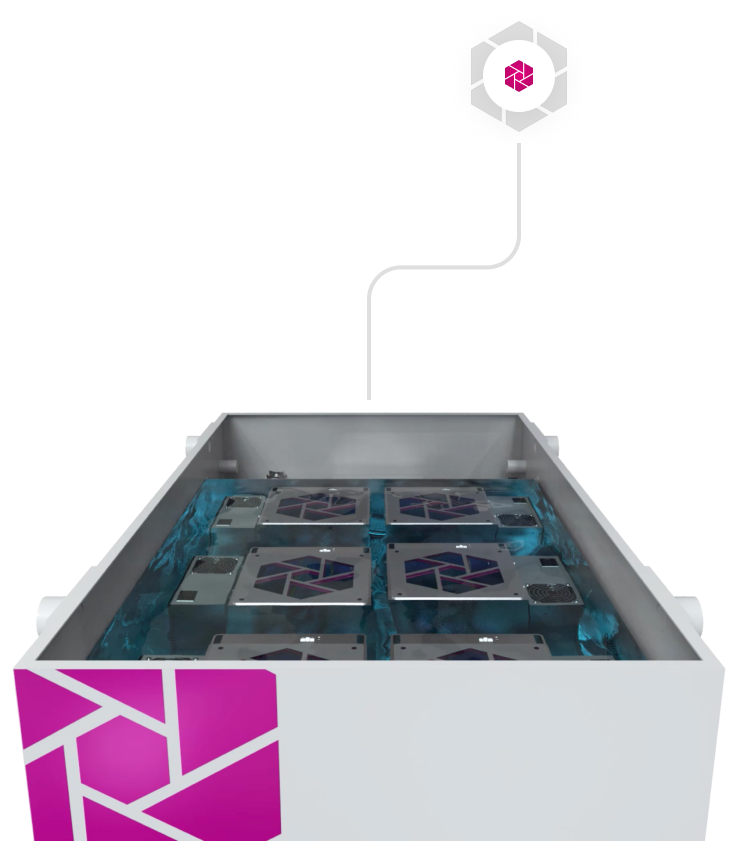

Products

Wide range of product availability of different capacities — cell, rack, container.

Components

Top quality components from leading European brands such as Siemens, Conex Banninger, ABB, Viega, SWEP, Eaton, IMI, Wilo, Grundfos.

All-round Solutions

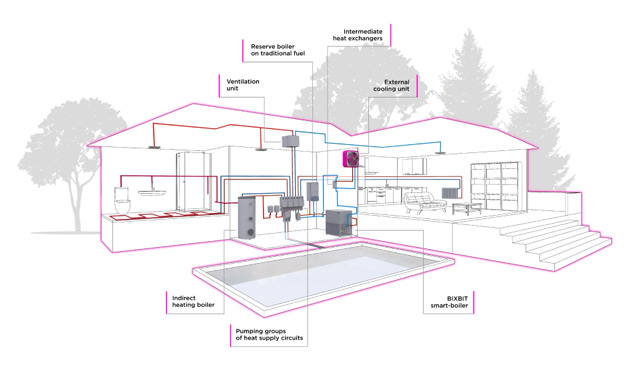

Ready-to-use products that do not require customization.

Durability

Prolonged lifespan of our equipment is ensured by the solid metal structure.

Project Design Work

Design work is an essential part of each large-scale project which is handled by our dedicated design department.

Expert Team

The team of qualified engineers who consider every aspect in the development of immersion cooling systems. We are confident in delivering the advertised performance in any location of the world.

Vertical Arrangement Design

The vertical design grants higher density for mining equipment placement, minimizes the risks associated with heat exchanger/pump failure, ensures steady temperature of immersion liquid in cells due to its short flow path from the miner to the heat exchanger.

Full-cycle Servicing

Comprehensive approach in organizing your mining farm: planning for a specific site, manufacturing based on the results of the design, delivery to the site and supervised launch. Customer support throughout the cooperation, software to enable remote monitoring / control of immersion and mining equipment.

Production Sites

We run our own production facilities in Europe.

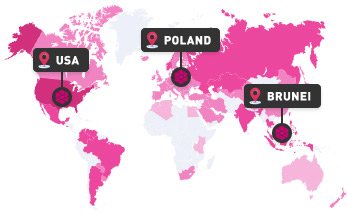

Global Presence

Representatives available in Europe, North America, and South Asia, offering on-site product demonstrations.

Personalization

Individual approach to meet the specific needs of each client.

Sales Geography

We deliver our products worldwide.