Summer brings serious challenges for miners, including equipment interruptions, overheating, downtime, and profit losses. Traditional ASIC cooling systems like air cooling often fail to keep hardware stable.

So why is immersion cooling the best solution for coping with summer heatwaves? By submerging your equipment in a dielectric liquid, immersion cooling keeps temperatures stable, protects your hardware, and boosts mining performance—making your ASICs ready to handle even the hottest days.

Table of Contents

Miners’ Concerns During Summer

Why Air Cooling is the Culprit

ASIC Cooling in Different Months: Things to Consider

5 Reasons to Switch to Immersion Cooling in Summer

As summer approaches, miners grapple with familiar challenges: ASIC interruptions, overheating, downtime, and profit losses. Traditional air cooling methods often fall short, straining resources and failing to meet expectations. The culprit is typically inefficient air cooling systems.

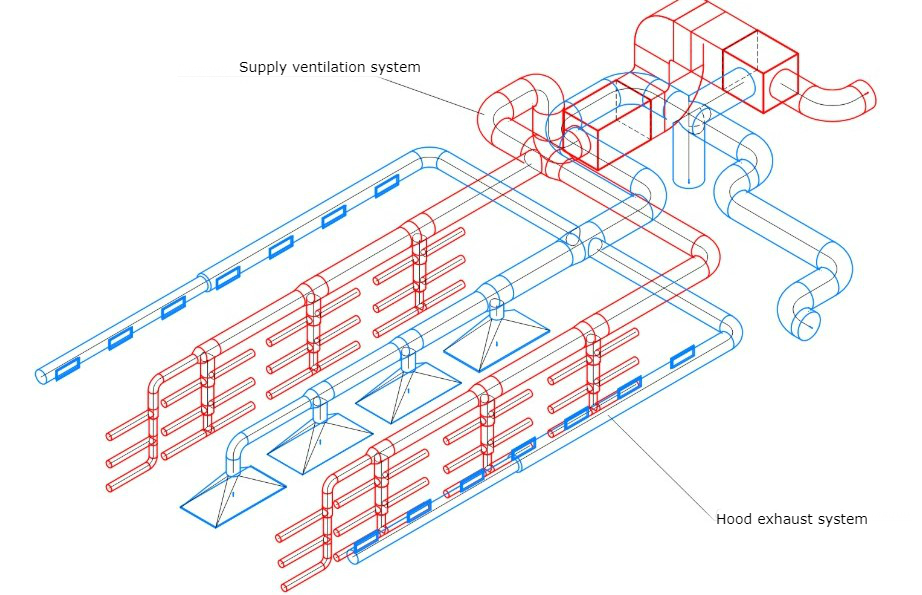

Sufficient climate control for mining functions comprises four integral tasks:

However, these systems encounter diverse issues during summer. The heat generated by different equipment blends with incoming air, heat removal strategies fail to perform properly, dust accumulates in ASIC units, and pricy air conditioning becomes a must to battle soaring temperatures. That’s why shifting to ASIC immersion cooling seems to be the only way to cope with these challenges during summer.

Although air cooling is employed in 95% of global mining farms, it comes with notable drawbacks, especially in managing equipment during varying seasonal conditions. Despite their purpose to maintain an unchanging microclimate and confirm year-round operational steadiness, air cooling systems encounter innate limitations.

For instance, the popular Antminer S9 ASIC model, with specifications including a power consumption of 1400W, an operating temperature scope of 0 to 40 degrees Celsius, and a cooling fan capacity of 338 cu.m per hour, generates substantial thermal output with almost all consumed electricity converted into heat. Failure to adequately dissipate this heat — 1400W per ASIC — can lead to unfavorable upshots such as growing ambient temperatures, equipment overheating, shutdowns, or outright failures.

Scaling up to manage multiple ASICs might even exacerbate the issue. To cool 100 ASICs, a ventilation and air conditioning system with a capacity of 150kW is necessary, requiring the circulation of approximately 34,000 cubic meters of air per hour. Inappropriate system design/installation can worsen issues, resulting in diminished equipment performance, increased error rates, accumulation of dust/debris, and premature equipment failure.

These flaws emphasize the need for alternative cooling solutions, especially in high-density mining environments where air cooling fails to maintain optimal operating conditions.

Temperature Control: Air cooling struggles in heatwaves; immersion cooling keeps ASICs at a stable temperature.

Overheating Protection: Air-cooled hardware risks shutdowns; immersion cooling prevents overheating and supports overclocking.

Environmental Impact: Air cooling consumes more electricity and creates noise; immersion cooling lowers energy use and reduces dust and noise.

Equipment Lifespan: Air cooling exposes ASICs to thermal stress; immersion cooling extends hardware life.

Operational Costs: Air cooling requires high electricity and maintenance; immersion cooling cuts costs by up to 50%.

When concerning the nuances of ASIC cooling, it's integral to scrutinize the seasonal variations and their influences on classic air-based cooling techniques.

The ambient temperature soars to 25-30 degrees Celsius in summer, which is what makes it more problematic to maintain optimal operating circumstances. All equipment generates heat and the ingress of warmer air exacerbates thermal management challenges, which possibly leads to noteworthy performance degradation.

In contrast, cooler ambient temperature streamlines the cooling strategy. However, the possibility of operating ASICs in sub-zero conditions comes with its own risks, specifically considering that condensation may damage susceptible electronics.

To fight the summer heat, mining installations employ effective ventilation systems with fans, filtering mechanisms, and automation controls that altogether regulate airflow and temperature. Despite that, it's still tough to maintain temperatures within the safe zone. More often than not, it's necessary to employ costly air conditioning systems to prevent overheating and have an uninterrupted operation.

With all the limitations of air cooling, immersion cooling has emerged as a perfect alternative. The technique involves submerging equipment in a dielectric liquid — without the need for ambient air temperature — to deliver steady and precise temperature control. This approach optimizes ASIC performance throughout the year and minimizes the risk of thermal fluctuations.

Immersion cooling efficiently dissipates heat through a specialized heat exchanger. Excess heat generated by the submerged ASICs can be reused for heating purposes. It can also be removed from the system via dry cooling towers to minimize environmental impact and maximize energy efficiency.

The mining industry thrives constantly and ASIC cooling technologies like immersion cooling become extremely paramount to maximize operational efficiency and profitability. Immersion cooling makes ASIC performance independent from environmental conditions and delivers a reliable approach for miners to manage thermal challenges.

Shifting to ASIC immersion cooling during summer comes with diverse benefits, five of which are:

| Enhanced Performance | Keeps ASICs at stable temperatures for maximum hashrate and overclocking. |

| Overheat Protection | Monitors and prevents overheating, extending hardware lifespan. |

| Exemplary Environmental Protection | Shields ASICs from dust, debris, and noise for a cleaner, quieter workspace. |

| Extended Equipment Lifespan | Rejuvenates older hardware, reducing downtime and maintenance needs. |

| Reduced Operating Costs | Cuts energy and maintenance expenses by up to 50%. |

Let's elaborate on each of these points.

As it's obvious now, immersion cooling is a paramount solution to summer mining challenges as it presents sweetened performance, environmental benefits, lengthened equipment lifespan, and reduced costs.

Miners can take advantage of BixBiT’s powerful immersion cooling systems to guarantee their operational stability and maximize their profitability during blazing summer days when ASIC cooling technologies find the most tremendous primacy.